RAMCO Cleaning Aerospace Heat Exchangers

Cleaning Heat Exchangers for Aerospace

This customer required precision cleaning of complex heat exchangers. The system had to remove a variety soils from the interior and exterior substrates. Different alloys such as aluminum, stainless steel and titanium had to be accommodated. Acceptable cleaning chemicals had to be used in accordance with stringent specifications. The two stage system shown below was developed at RAMCO and uses standard and lateral turbo/filtration.

The heart of each system is the adroit use of the elevator within each processing chamber. The elevator is used to transport components into and out of each chamber. However, its most important function is to position and move the components within the working zone. It is this dynamic aspect of its function that allows RAMCO systems to achieve superior results in washing, rinsing and drying. We call this Dynamic Flow Combination. The effect of Dynamic Flow Combination is better coverage of component surfaces, more consistent results and accelerated processing times.

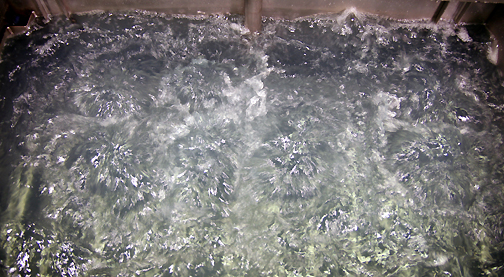

The elevators in this process positioned and gently moved the heat exchangers up and down within the working zone. The washing stage uses standard and special lateral turbo jets to direct solution into various recessed areas of the heat exchangers. The turbo uses a high volume all stainless steel pump and closed looped manifolds with multiple jets. The system provides an even flow of turbulent solution over, under, around and through the heat exchangers.

RAMCO turbo system are proven to accelerate processing times in washing and rinsing.

Filtration is provided using bag elements in a large 7 x 32 housing. The rinse water is also filtered using a smaller housing. Vertical immersion pumps are used in both stages as part of the Turbo/Filter systems. The use of vertical pumps eliminates seal problems inherent with centrifugal pumps. This is especially beneficial when using high pH, low pH or abrasive chemicals.

A stand alone hot air knife dryer was also designed for the process. RAMCO Hot Air Knife Blow-Off Dryers get maximum evaporation providing rapid drying without excessive heat. The key is using high volume hot air combined with changing air flow patterns created by the oscillating elevator. Air is recirculated, heated and directed into the drying chamber via adjustable air knives.

The elevator constantly oscillates the workload in and out of the hot air stream. Humid air is displaced with just the right amount of fresh air using adjustable vents to maintain effective air quality within the chamber. The dryer is electrically heated and includes a digital indicating temperature controller, high temperature manual reset and an air flow proving switch to protect heaters.