RAMCO Tenacious Carbon Removal from Aerospace Heat Exchangers

Backflushing

The process incorporates an automatic flushing and backflushing system designed to remove loosened soils from deep within the heat exchangers. This is done automatically during the process sequence. The process sequence starts with powerful ultrasonics to both clean the exterior and interior of the heat exchanger. Then loosened soil is automatically and repeatedly flushed and backflushed for a timed cycle. The overall process is then repeated using rollovers (see below).

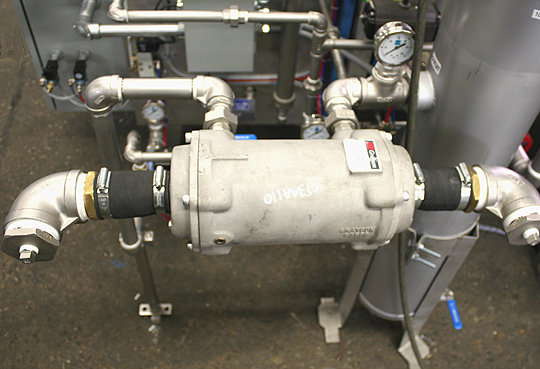

Quick connect/disconnect hoses are hooked up to both sides of the heat exchanger

Ultrasonics

The unique RAMCO ultrasonic cleaning system cascades powerful sweep frequency (between 38 to 42 kHz) ultrasonics with agitation/turbo/flushing/washing. Using mechanical agitation washing to remove gross contamination and ultrasonic cleaning to remove finer and/or more resistive deposits is a very effective processing routine. The steps are sequenced with digital timers for agitation/turbo/flushing/washing before after the ultrasonic phase. And using our MultipleRollover feature the dual mode process can be repeated for any number of preset “rollovers”. The results are faster cleaning and more effective overall processing.

A high volume all stainless steel vertical immersion pump is used with a large stainless steel filter canister. To handle residual heat build-up from turbulation and/or ultrasonics an auxiliary cooling system (either connected to a chiller or cold water source) is included. A compact heat exchanger is used for this application and is placed in line with the filtration unit. It automatically controls any excess heat build up in the solvent if encountered during the process.

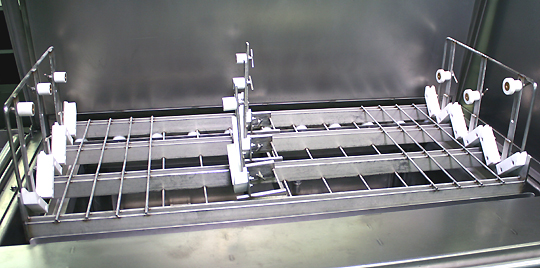

Other features include dual pneumatic power covers with light curtain safety interface, digital indicating temperature controllers, digital sequenced cycle timers, platform roller conveyors for easy transfer, both overhead and lip ventilation and a custom work carrier (see below). The system is CE certified.