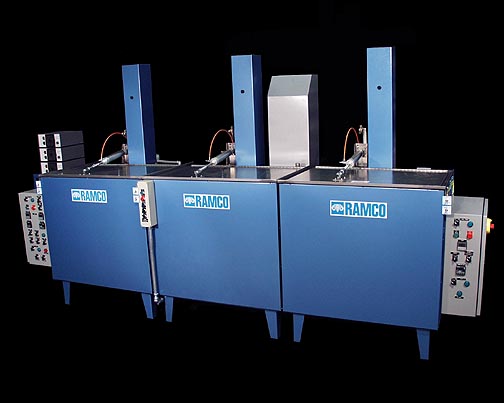

RAMCO Equipment Parts Washing Rinsing and Drying System

RAMCO has been building its unique style of ultrasonic systems for over a decade. Key to the success of these systems has been the use of our standard process elevator. The elevator is sequenced to alternate powerful sweep frequency ultrasonic cleaning with turbo/filter/agitation washing. The turbo/agitation washing removes gross contaminants and the ultrasonic cleaning the finer and/or more resistive contaminants. The results of this very effective processing is a routine that produces faster cleaning and more consistent processing. The system uses digital cascading timers for the turbo/filter/agitation washing and ultrasonic cleaning phases.

The ultrasonic phase can be set to provide vertical oscillation of the work during the sonic cycle. A selector switch is provided for static ultrasonic or oscillating ultrasonic modes. And using our MultipleRollover feature the complete dual mode process can be repeated for any number of preset “rollovers”. RAMCO ultrasonic system routinely provide superior ultrasonic washing action over conventional (static) systems by moving the work through the peaks and nodes of the wave energy

RAMCO Hot Air Knife Blow-Off Dryers have been proven to be very effective for rapidly drying parts. The key to the process is the process elevator. It is used to produce changing flow patterns that result in dynamic drying (i.e. platform oscillation combined with hot air flow). The effect of “dynamic flow combination” is better coverage of component surfaces, maximum evaporation and accelerated processing times.

Ramco Dryers get maximum evaporation for rapid drying without excessive heat. Air is recirculated, heated and directed into the drying chamber via adjustable air knives. The elevator constantly oscillates the workload in and out of the hot air stream. Humid air is displaced with just the right amount of fresh air using adjustable vents to maintain effective air quality within the chamber. The dryer is electrically heated and includes a digital indicating temperature controller, high temperature manual reset and an air flow proving switch to protect the heating elements.