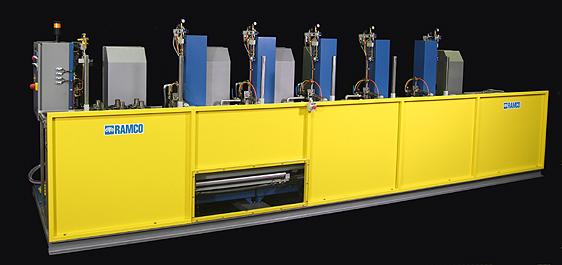

RAMCO Automated Semi Aqueous Wash/Wash/Rinse/Dry/Dry System

Solvent Washing System

This fully automated wash/wash/rinse/dry/dry system was built for an automotive parts manufacturer. It thoroughly removes contaminants from harmonic balancers. The system uses a high flashpoint semi aqueous solvent wash, a water rinse, and dual hot air knife blow- off dryers. Pneumatically powered covers automatically sequence with the positioning of the elevators to reduce emissions and save on energy.

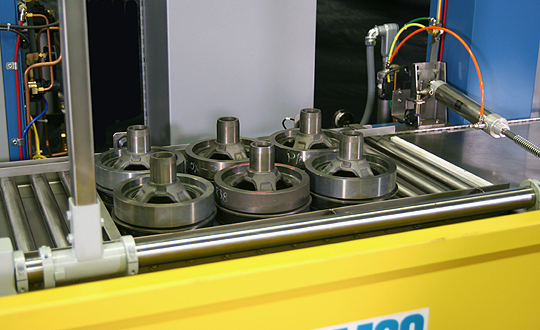

The system is designed to automatically process six components per load and does not require a basket or rack for transfer (see below). Transfer is accomplished using our patented Ram Tough multi-arm articulating walking beam with Automation Ready connectors.

The Operators Control Panel is shown below. It is divided into a Run Section and a Debug Section. The operator simply uses start and stop pushbuttons to run the system. An Allen-Bradley MicroLogix 1100 controls the automation program. The system includes manual and automatic modes with selector switches to directly control the transfer functions for manual operation and/or debug.